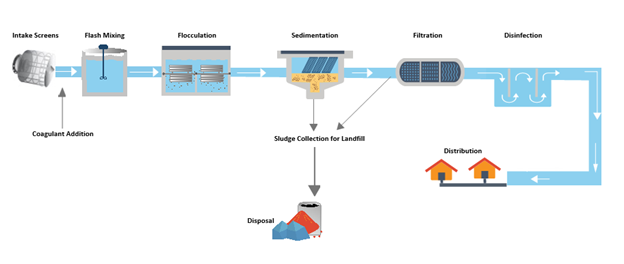

Super High Efficiency Water Treatment Plant (WTP) Solution

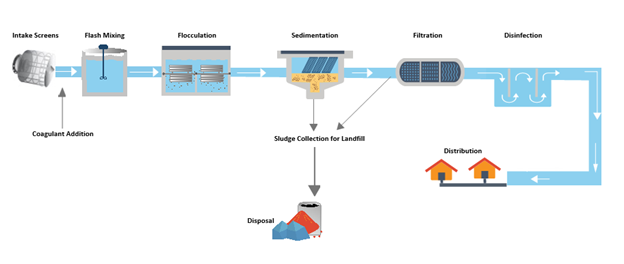

Nova Industries, in collaboration with our esteemed partners Parkson Corporation, Meurer Research International (MRI), and Teknofanghi, proudly presents the Super High Efficiency Water Treatment Plant (WTP) Solution. This cutting-edge system is designed to meet the highest standards in water treatment, ensuring superior performance, sustainability, and cost-effectiveness. Let’s delve into the key components that make this solution unparalleled in the industry.

Parkson’s Aqua Guard Screen: Optimal Water Intake

At the water intake channels, the Parkson Aqua Guard Screen ensures the first line of defense. This advanced screening technology effectively removes debris and particles from the incoming water, preventing damage to downstream equipment and ensuring smooth operation. Its self-cleaning mechanism and robust design minimize maintenance needs and enhance operational efficiency. The result is cleaner intake water, reduced wear and tear on equipment, and increased overall plant reliability.

MRI Flash Mixer: Efficient Coagulation

Following the initial screening, the MRI Flash Mixer takes charge of the coagulation process. This high-performance mixer rapidly and uniformly disperses coagulants into the water, facilitating the agglomeration of fine particles. Its precise control over mixing intensity and duration ensures optimal coagulation, leading to improved particle removal in subsequent stages. The key benefits include enhanced water clarity, reduced chemical usage, and improved downstream treatment efficiency.

Paddle Flocculator: Effective Flocculation

The Paddle Flocculator is designed to gently mix the water, promoting the formation of larger, more settleable flocs. Its slow, controlled agitation allows for the delicate aggregation of particles without causing shear, ensuring maximum floc growth. This process is critical for effective sedimentation, as it enhances the removal of suspended solids. The Paddle Flocculator’s efficiency results in clearer water with fewer impurities, setting the stage for superior clarification.

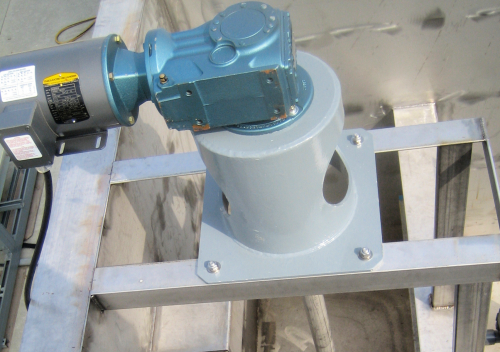

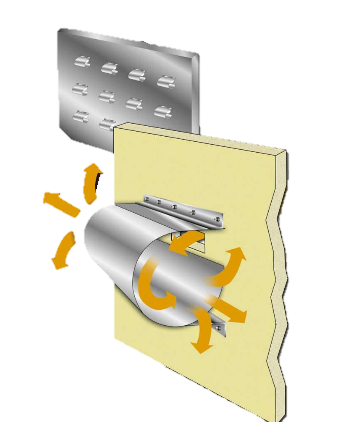

Inlet Diffuser: Precise Velocity Reduction

To achieve optimal clarification, the Inlet Diffuser plays a pivotal role by reducing the velocity of the incoming water. This component evenly distributes the flow, minimizing turbulence and allowing for uniform settling of particles. By creating a calm environment, the Inlet Diffuser enhances the effectiveness of the Lamella Plate Cartridges in the subsequent stage, leading to better clarification and higher quality effluent.

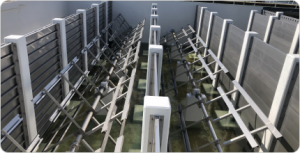

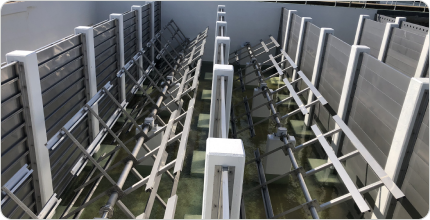

Lamella Plate Cartridges: Advanced Clarification

Lamella Plate Cartridges are a key innovation in our WTP solution, providing efficient and compact clarification. These plates increase the surface area available for particle settling, significantly improving the clarification process. Their modular design allows for easy scalability and maintenance. The outcome is a highly efficient clarification stage that produces crystal-clear water, ready for further filtration.

HCV Sludge Collector: Effective Sludge Collection

Sludge collection is managed by the HCV Sludge Collector, which efficiently gathers and removes settled sludge from the clarifiers. Its robust construction and efficient operation ensure continuous sludge removal, preventing buildup and maintaining optimal clarifier performance. The collected sludge is then ready for dewatering, ensuring a clean and efficient process.

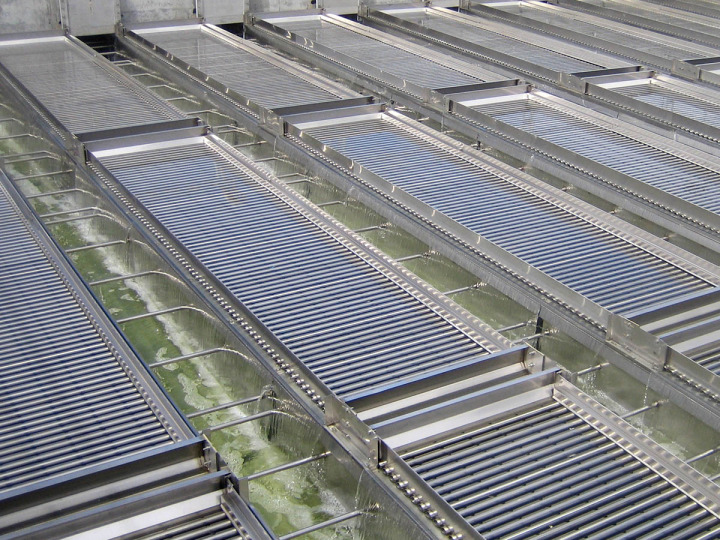

Parkson DynaFilter: Superior Filtration

Post-clarification, the water undergoes filtration through the Parkson DynaFilter. This continuous backwashing filter provides high-quality filtration with minimal maintenance. It effectively removes remaining suspended solids, producing water that meets stringent quality standards. The DynaFilter’s self-cleaning capability ensures consistent performance and long-term reliability, making it a cornerstone of our WTP solution.

Teknofanghi MonoBelt: High-Performance Sludge Dewatering

The Teknofanghi MonoBelt system dewaters the sludge byproduct, producing a final sludge with a high dried solids concentration. This dewatering process reduces sludge volume, minimizes disposal costs, and produces a manageable byproduct. The MonoBelt’s efficient operation and high dewatering performance contribute to the overall sustainability and cost-effectiveness of the treatment plant.

Disinfection: Ensuring Safe Drinking Water

The final water disinfection stage employs either Chlorine Dosing or UV Disinfection to ensure the treated water meets and exceeds the United Nations World Health Organization (WHO) standards for drinking water. These disinfection methods effectively eliminate pathogens, ensuring the safety and quality of the water for consumption. The choice of disinfection method can be tailored to specific needs, providing flexibility and assurance in water treatment.

Synergistic Integration for Optimal Performance

The Super High Efficiency Water Treatment Plant (WTP) Solution is a testament to the power of integrated, advanced technologies working in harmony. Each component is meticulously selected and engineered to complement the others, creating a seamless and highly efficient water treatment process. From the initial screening to final disinfection, every stage is optimized for maximum performance and reliability.

This integrated approach ensures the highest quality of effluent, consistently meeting and exceeding regulatory standards. The plant’s design life of 30 years guarantees long-term operational stability and resilience. Moreover, the innovative technologies employed in our WTP solution result in the lowest operational expenses in the industry, making it a cost-effective choice for municipalities and industries alike.

In summary, Nova Industries’ Super High Efficiency Water Treatment Plant (WTP) Solution is a pinnacle of modern water treatment technology. It combines cutting-edge components, robust design, and efficient operation to deliver clean, safe, and high-quality drinking water. This solution not only meets today’s demands but is also poised to address future challenges in water treatment with unparalleled efficiency and sustainability.

Super High Efficiency Water Treatment Plant (WTP) Solution

Synergistic Integration for Optimal Performance

The Super High Efficiency Water Treatment Plant (WTP) Solution is a testament to the power of integrated, advanced technologies working in harmony. Each component is meticulously selected and engineered to complement the others, creating a seamless and highly efficient water treatment process. From the initial screening to final disinfection, every stage is optimized for maximum performance and reliability.

This integrated approach ensures the highest quality of effluent, consistently meeting and exceeding regulatory standards. The plant’s design life of 30 years guarantees long-term operational stability and resilience. Moreover, the innovative technologies employed in our WTP solution result in the lowest operational expenses in the industry, making it a cost-effective choice for municipalities and industries alike.

In summary, Nova Industries’ Super High Efficiency Water Treatment Plant (WTP) Solution is a pinnacle of modern water treatment technology. It combines cutting-edge components, robust design, and efficient operation to deliver clean, safe, and high-quality drinking water. This solution not only meets today’s demands but is also poised to address future challenges in water treatment with unparalleled efficiency and sustainability.