Baffles

For Optimized Flow Management

When strategically placed in flocculators, clarifiers, and aerators, MRI baffles enhance flow distribution control and treatment duration at various stages. Constructed from all stainless steel, MRI’s plank baffles outperform redwood, fiberglass, or concrete alternatives, offering quick and easy installation or reconfiguration, conservation of natural resources, and prevention of chemical contamination. Suitable for new installations or retrofits, MRI baffles can be slotted, ported, or solid, depending on the application.

To increase clarifier efficiency, the following Flow management devices are available:

MRI baffles operate by strategically managing and directing water flow in treatment basins such as flocculators, clarifiers, and aerators. Their primary function is to enhance flow distribution and treatment duration, ensuring efficient solids removal and overall process optimization. Here’s how they work:

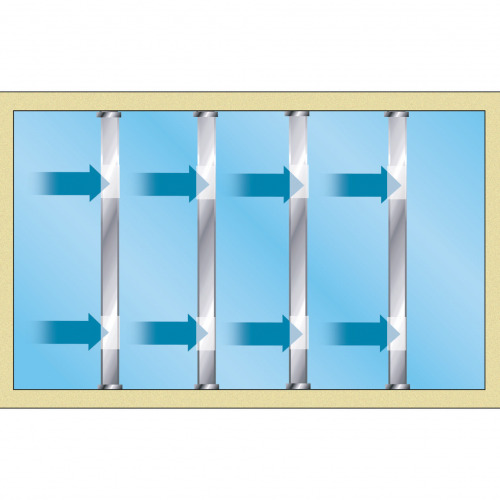

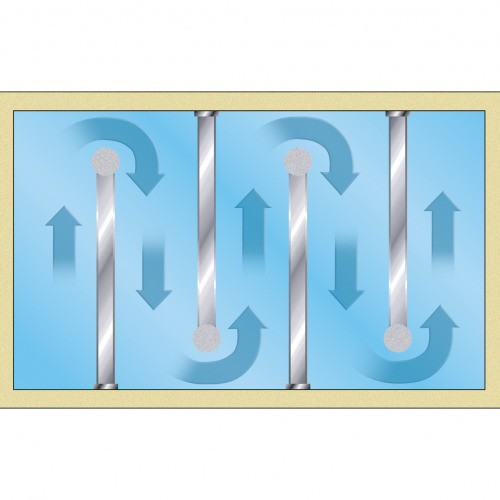

MRI baffles are placed in specific configurations within the treatment basins to control and direct the water flow. This strategic placement helps to distribute the flow evenly, preventing short-circuiting and ensuring that all areas of the basin are effectively utilized.

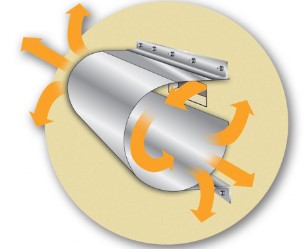

The patented design of MRI’s port helical flow diffusers and inlet infusers splits the incoming flow and reduces its velocity. This is achieved by gently splitting the flow in half and exiting in a spiraling motion, covering a 180° area at the exit point. The reduced velocity prevents the disruption of floc formation and ensures even flow distribution.

As the water passes through, solids drop out of suspension and are collected in the sludge zone. This leads to clearer effluent exiting the clarifier.

Ensures compliance with health and safety standards.

Made of 304/316 stainless steel for long-lasting performance

Quick and simple to install or reconfigure.