DynaFilter®

Continuous Backwash Filter

The Parkson DynaFilter® ’s innovative design and continuous self-cleaning operation make it an ideal choice for achieving high-efficiency filtration with minimal maintenance. Its ability to provide consistent, high-quality effluent ensures reliable performance in a variety of wastewater treatment applications.

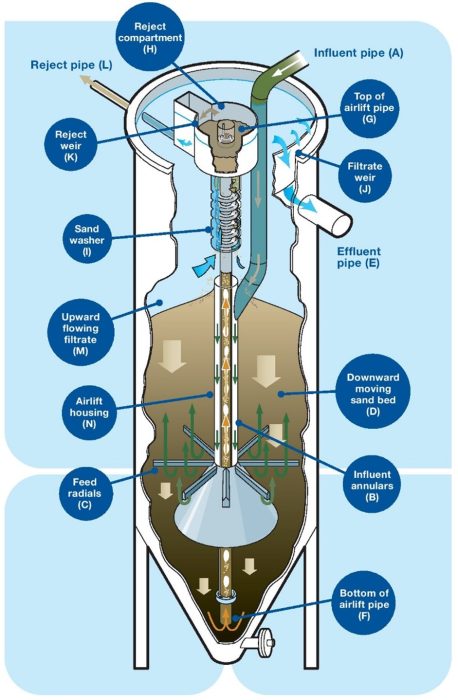

The DynaFilter® is a continuous upflow, deep bed, granular media filter. It is designed to provide high-quality filtration with minimal operator intervention, ensuring consistent performance in a variety of wastewater treatment applications. Here’s how the DynaFilter® operates:

The continuous upflow design ensures steady removal of particulates, providing consistently high-quality effluent.

Unlike Rapid Gravity Filters and Multimedia Pressurized Sand Filters, the DynaSand® Filter does not require periodic backwashing, which reduces operational interruptions and maintenance efforts.

The self-cleaning system allows for continuous filtration, ensuring a constant supply of treated water without the need for shutdowns for cleaning.

Reduced energy consumption translates into lower operational costs compared to the energy-intensive backwashing processes required by Rapid Gravity Filters and Multimedia Pressurized Sand Filters.

The energy-efficient design contributes to the sustainability goals of the facility, reducing its overall environmental impact.

The fine sand media provides excellent removal of suspended solids, resulting in superior water clarity and quality.

The high filtration efficiency makes the DynaSand® Filter suitable for a wide range of applications, including municipal, industrial, and process water treatment.

The DynaSand® Filter requires less maintenance compared to other filtration systems.

The low maintenance requirements minimize operational downtime, ensuring continuous and reliable performance.

Lower maintenance needs result in cost savings over the lifespan of the filter, making it an economically attractive option.