Flocculators / Mixers

For Precision Flocculation

The MRI Flocculation System offers an advanced, efficient, and adaptable solution for optimizing the flocculation process in water treatment plants. Its multi-stage approach, combining mechanical and hydraulic mixers, provides precise control over the entire pretreatment process, ensuring effective floc formation and sedimentation. With key features like variable speed mixers, a self-cleaning hydraulic stage, and flexible configuration options, the MRI Flocculation System delivers enhanced performance, energy efficiency, and reduced maintenance requirements.

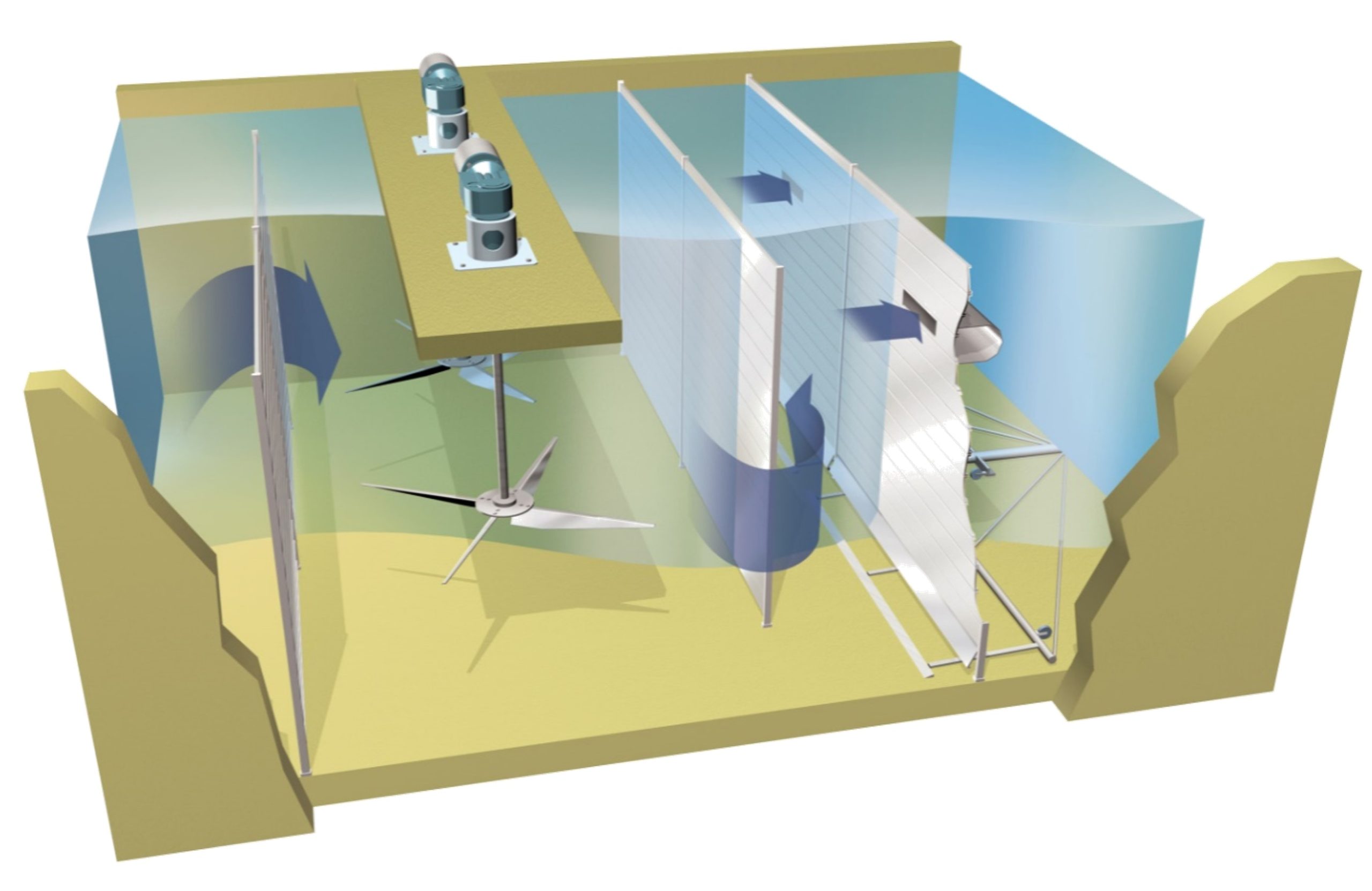

Mix and Match with our Flocculator systems. MRI Flocculation Systems can use vertical turbine, horizontal paddle wheel, or hydraulic flocculation or a combination in the first three stages, allowing for a wide range of G-values. Basin configuration or preference can determine which device is best suited.

The MRI Flocculation System is designed to optimize the flocculation process by integrating multiple stages of mechanical and hydraulic mixing. This multi-stage approach allows for precise control over the mixing intensity (G-values), ensuring effective formation and growth of flocs, which are essential for subsequent sedimentation and filtration processes.

High-G Vertical Turbine Mixers: Utilize extremely high G-values to quickly disperse chemicals and initiate floc formation.

High-G Vertical Turbine Mixers: Maintain high turbulence to encourage initial floc growth.

Mid-G Horizontal Paddle Wheel Mixers: Operate at lower G-values to gently mix and grow flocs without causing shear.

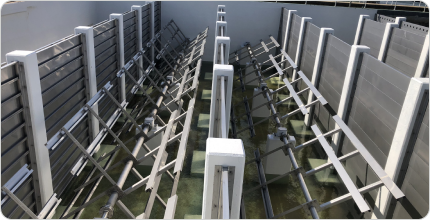

Extremely Low-G Hydraulic Mixers: Utilize self-cleaning hydraulic mechanisms to create a quiet zone with minimal turbulence.

Allows operators to optimize flocculation stages for maximum efficiency, improving overall water treatment performance.

The self-cleaning hydraulic stage consumes no energy and reduces the energy requirements of mechanical mixers.

o The self-cleaning design and robust construction minimize maintenance needs and operational downtime.

By optimizing the flocculation process, the system enhances the removal of suspended solids and other impurities, leading to higher quality effluent.

The ability to adjust G-values and mixing intensity ensures consistent performance even with seasonal variations in raw water quality.

Includes high-G vertical turbine mixers, mid-G horizontal paddle wheel mixers, and low-G hydraulic mixers.

Separates stages and controls flow, ensuring even distribution and optimal hydraulic conditions

Systems can be customized with various combinations of flocculators to suit specific needs.