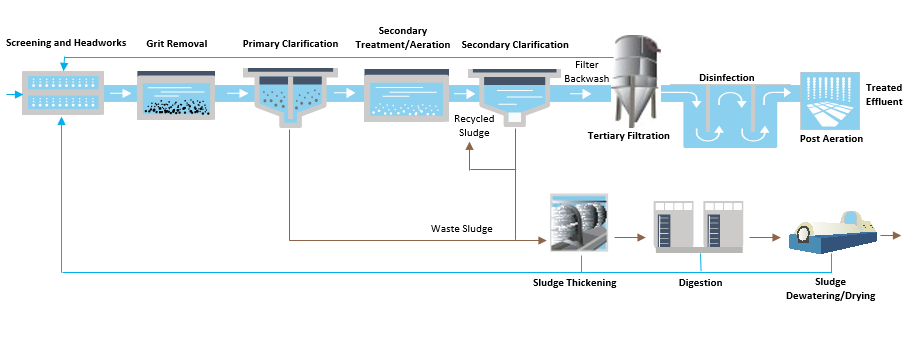

Introducing the Ideal Wastewater Treatment Plant (WWTP) Solution

Nova Industries, in partnership with Parkson Corporation, OTT Aeration, INVENT, and Teknofanghi, is proud to introduce the Ideal Wastewater Treatment Plant (WWTP) Solution. This cutting-edge system combines advanced technologies to provide an efficient, sustainable, and robust wastewater treatment process, ensuring the production of high-quality effluent that meets and exceeds standards for treated water reuse.

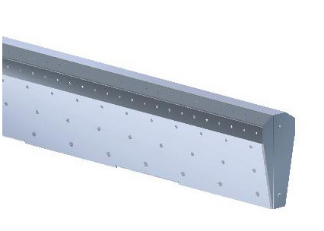

Parkson’s AquaGuard Screen

The treatment process begins with the AquaGuard Screen from Parkson Corporation, installed at the water intake channels. This innovative screening system effectively removes large debris and contaminants, protecting downstream equipment and enhancing overall process efficiency. The AquaGuard Screen features high capacity, low maintenance requirements, and robust construction, ensuring reliable operation even in challenging conditions. The result is a cleaner, safer starting point for wastewater treatment, significantly reducing the burden on subsequent processes.

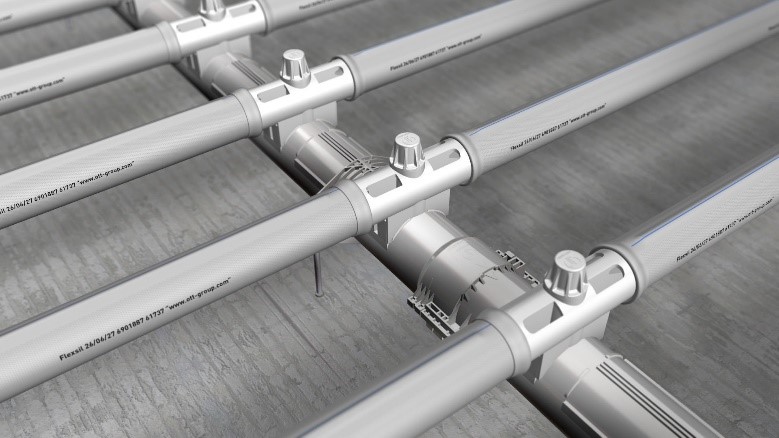

INVENT Coarse Bubble Diffusers in Equalization Basins

In the equalization basins, INVENT Coarse Bubble Diffusers play a crucial role in homogenizing the wastewater and preventing sedimentation. These diffusers provide efficient oxygen transfer and mixing, ensuring uniform wastewater composition and enhancing the performance of downstream biological treatment processes. Key benefits include high oxygen transfer efficiency, low energy consumption, and durability. The result is a stable and well-mixed influent, which optimizes the conditions for effective biological treatment.

INVENT Mixer for Anoxic Stage

During the anoxic stage, the INVENT Mixer ensures thorough mixing to facilitate denitrification. This high-performance mixer creates an ideal environment for the biological removal of nitrogen compounds. Its key features include efficient mixing capabilities, energy efficiency, and low maintenance requirements. The INVENT Mixer ensures optimal anoxic conditions, leading to effective nitrogen removal and improved overall treatment performance.

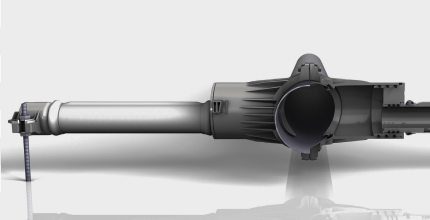

OTT Magnum Tube Diffusers for Aeration Tanks

The OTT Magnum Tube Diffusers in the aeration tanks provide superior aeration performance, promoting the growth and activity of aerobic microorganisms. These diffusers offer high oxygen transfer efficiency, uniform bubble distribution, and long service life. The Magnum Tube Diffusers ensure effective biological oxidation of organic pollutants, resulting in significant reductions in biochemical oxygen demand (BOD) and chemical oxygen demand (COD). The result is high-quality effluent ready for further treatment.

INVENT SBR Decanter

In the sequencing batch reactor (SBR) stage, the INVENT SBR Decanter efficiently separates treated water from sludge. This advanced decanter ensures precise and reliable decanting, minimizing sludge carryover and optimizing effluent quality. Key features include automated operation, high decanting accuracy, and robust construction. The INVENT SBR Decanter contributes to consistent production of high-quality effluent, ready for tertiary treatment.

INVENT Disc Filter for Tertiary Filtration

Following secondary treatment, tertiary filtration is achieved with the INVENT Disc Filter. This state-of-the-art filtration system provides high-efficiency removal of fine particles, ensuring exceptional effluent quality. Key features include high filtration surface area, low energy consumption, and compact design. The Disc Filter effectively removes residual suspended solids, pathogens, and nutrients, producing effluent that meets stringent reuse standards.

Teknofanghi MonoBelt for Sludge Dewatering

The sludge byproduct from the treatment process is dewatered using the Teknofanghi MonoBelt. This advanced dewatering system produces sludge with a high dried solids concentration, significantly reducing volume and disposal costs. Key features include high dewatering efficiency, low energy consumption, and ease of operation. The Teknofanghi MonoBelt provides a cost-effective and environmentally friendly solution for sludge management, enhancing overall sustainability.

Chlorine Dosing or UV Disinfection

The final step in the treatment process involves disinfection, which can be achieved using either chlorine dosing or UV disinfection. Both methods effectively eliminate harmful pathogens and microorganisms, ensuring the safety and quality of the treated water. Chlorine dosing provides a reliable and cost-effective disinfection solution, while UV disinfection offers a chemical-free alternative with minimal environmental impact. The choice of disinfection method can be tailored to meet specific regulatory and operational requirements, providing flexibility and ensuring compliance with reuse standards.

Integrated System for Optimal Performance

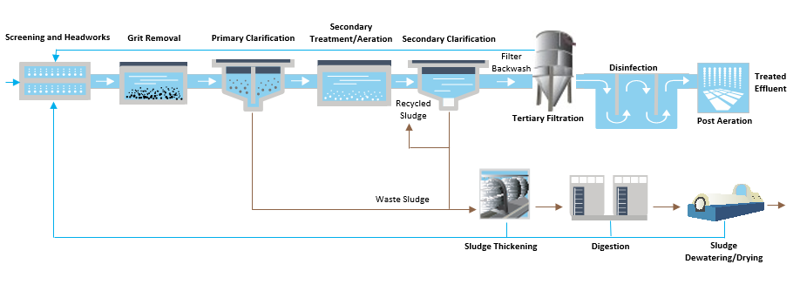

The Ideal Wastewater Treatment Plant Solution integrates these advanced technologies into a cohesive and highly efficient system. Each component is meticulously selected and engineered to work in harmony, ensuring seamless operation and optimal performance. The AquaGuard Screen initiates the process by removing large debris, followed by effective mixing and homogenization in the equalization basins with INVENT Coarse Bubble Diffusers. The anoxic stage, facilitated by the INVENT Mixer, ensures efficient nitrogen removal, while the OTT Magnum Tube Diffusers provide superior aeration in the aerobic stage. The INVENT SBR Decanter ensures precise separation of treated water from sludge, and the INVENT Disc Filter achieves high-efficiency tertiary filtration. The Teknofanghi MonoBelt efficiently dewaters the sludge byproduct, and the final disinfection stage ensures the safety and quality of the treated water.

This integrated approach results in a wastewater treatment plant that delivers the highest quality effluent, meeting and exceeding reuse standards. The system’s design life of 30 years and the lowest operational expenses in the industry make it a cost-effective and sustainable solution. The Ideal Wastewater Treatment Plant Solution represents the pinnacle of wastewater treatment technology, providing communities with a reliable, efficient, and environmentally friendly source of treated water suitable for reuse.

Introducing the Ideal Wastewater Treatment Plant (WWTP) Solution

Synergistic Integration for Optimal Performance

The Ideal Wastewater Treatment Plant Solution integrates these advanced technologies into a cohesive and highly efficient system. Each component is meticulously selected and engineered to work in harmony, ensuring seamless operation and optimal performance. The AquaGuard Screen initiates the process by removing large debris, followed by effective mixing and homogenization in the equalization basins with INVENT Coarse Bubble Diffusers. The anoxic stage, facilitated by the INVENT Mixer, ensures efficient nitrogen removal, while the OTT Magnum Tube Diffusers provide superior aeration in the aerobic stage. The INVENT SBR Decanter ensures precise separation of treated water from sludge, and the INVENT Disc Filter achieves high-efficiency tertiary filtration. The Teknofanghi MonoBelt efficiently dewaters the sludge byproduct, and the final disinfection stage ensures the safety and quality of the treated water.

This integrated approach results in a wastewater treatment plant that delivers the highest quality effluent, meeting and exceeding reuse standards. The system’s design life of 30 years and the lowest operational expenses in the industry make it a cost-effective and sustainable solution. The Ideal Wastewater Treatment Plant Solution represents the pinnacle of wastewater treatment technology, providing communities with a reliable, efficient, and environmentally friendly source of treated water suitable for reuse.